16 Types of Plastic Processing Techniques (Part 1)

Plastic molding starts with the right process selection and succeeds with smooth demolding. We have compiled the 16 most comprehensive plastic processing techniques in the industry to help you understand manufacturing logic. However, remember: no matter which process you choose, the application of plastic release agents, rubber release agents, and composite material release agents is especially important. Understanding the process ensures you make the right product, while choosing our high-quality release agents guarantees every mold opens smoothly, allowing productivity and quality to improve simultaneously.

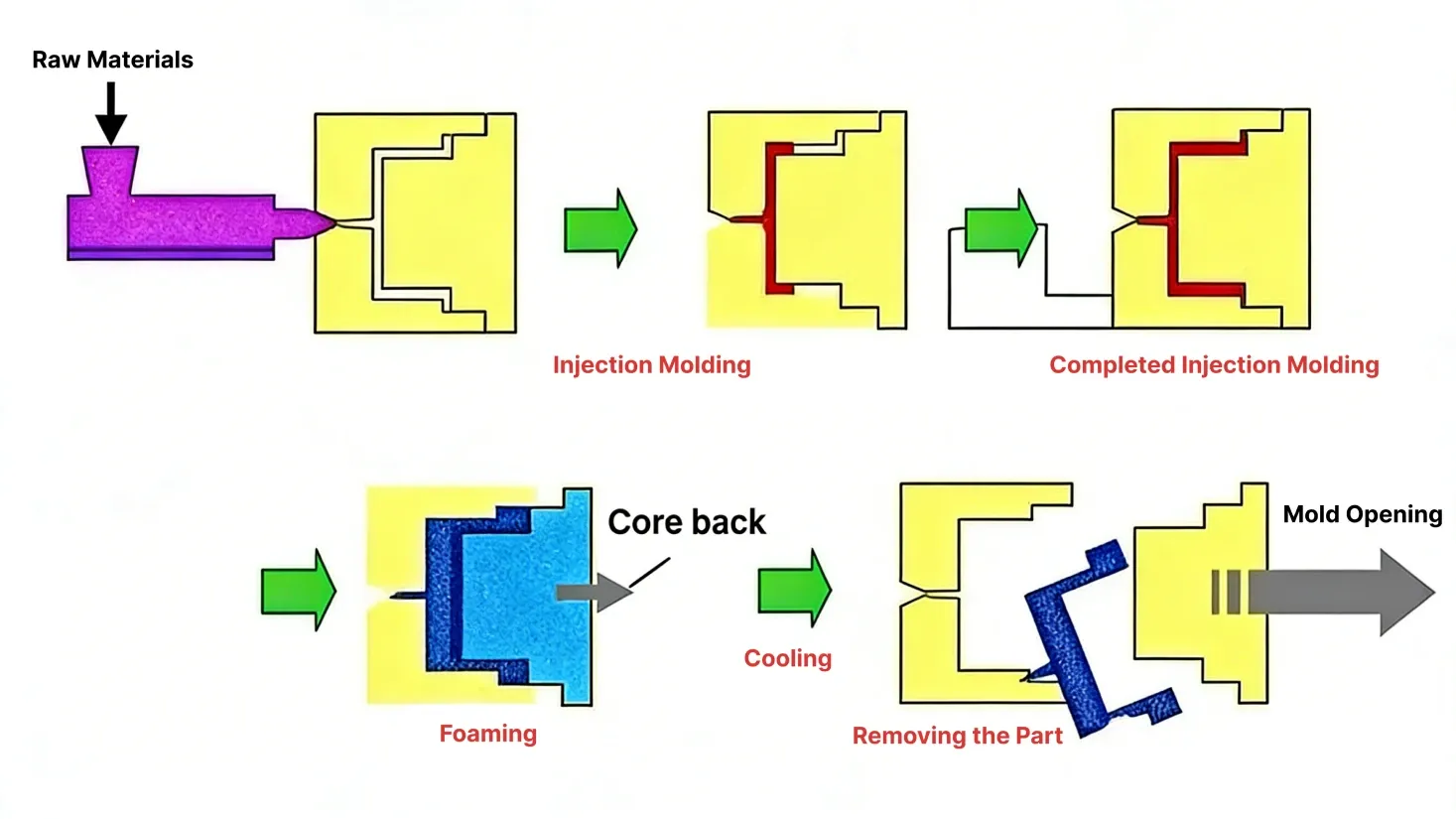

1. Injection Molding Process

Injection molding is the most widely used plastic forming method. Injection molding machines use molds to shape thermoplastic or thermosetting plastics into various plastic products.

It’s similar to playing with clay as a child: put a lump of clay (plastic melt) into a shaped box (mold), press it down (clamping and injection), then open the lid (mold opening) to get the desired product.

2. Extrusion Molding Process

Extrusion molding pushes the material through the barrel and screw of an extruder. The material is heated and plasticized while being pushed forward, then continuously shaped through the die to produce semi-finished products, commonly used for pipes and sheets.

Think of squeezing toothpaste: when you push the tube (screw feeding), the toothpaste (polymer melt) comes out in a cylindrical or other shapes.

3. Blow Molding Process

Also known as hollow blow molding, this rapidly developing method uses a tubular plastic preform made by extrusion or injection. After heating to soften, it is placed in a mold, then compressed air is injected to expand the plastic against the mold walls. After cooling and demolding, various hollow products such as bottles are obtained.

This process is like making square watermelons: an oval-shaped preform (plastic tube) is placed in a square mold, then expanded (blown) into the mold shape, resulting in a square-shaped watermelon (bottle).

4. Vacuum Forming (Thermoforming) Process

This technique heats a flat plastic sheet until soft, then uses vacuum suction to pull it onto a mold surface. After cooling, it retains the mold shape. This process is widely used in various industries.

It’s like making a fried egg: the liquid egg (softened plastic sheet) is poured into shaped cookware (mold), heated (softened by vacuum), and cooled to form the desired shape.

5. Compression Molding Process

Also called press molding, this method places powdered, granular, or fibrous plastic into a heated mold cavity. The mold is closed, and pressure is applied to form and cure the product. Suitable for thermosets, thermoplastics, and rubber materials.

Similar to injection molding but primarily for thermosetting resins: place the material in a shaped mold, apply heat and pressure, then cool to get the finished product.

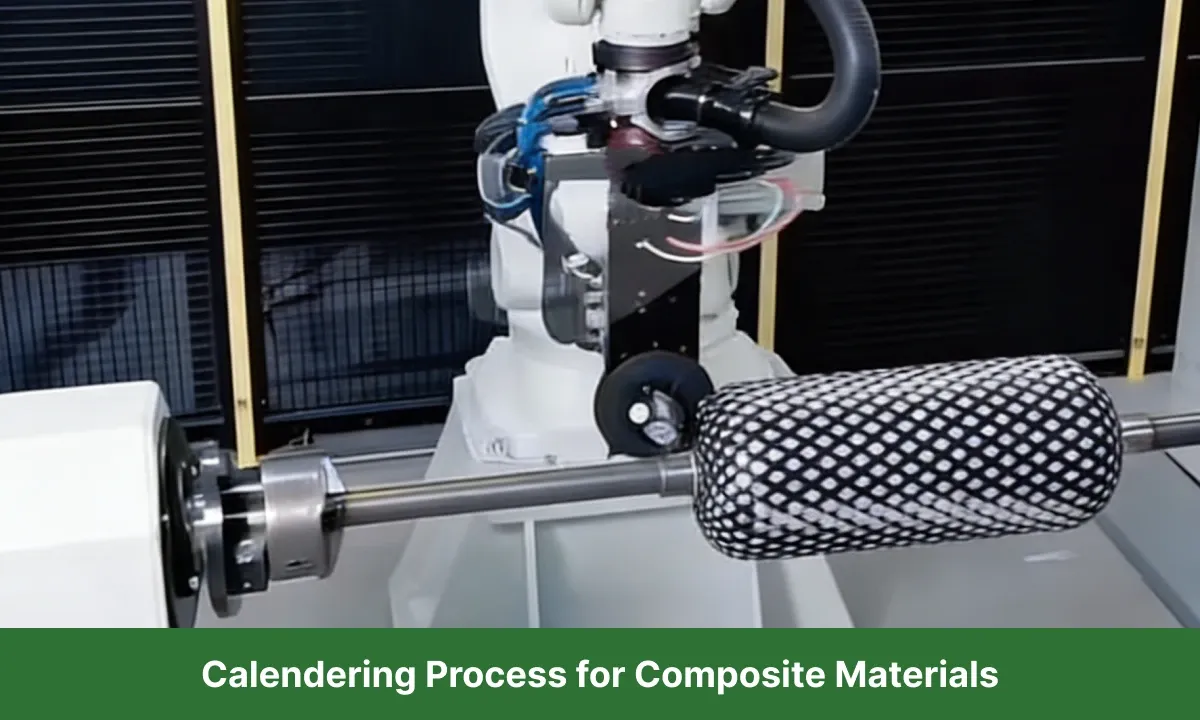

6. Calendering Process

Calendering passes heated thermoplastic material between two or more counter-rotating rollers, stretching and compressing it into sheets of required dimensions and quality, then allowing it to cool naturally. Often used for plastic films or PVC sheets.

Compared to extrusion, calendering uses rollers to thin and shape the extruded material.

7. Foam Molding Process

Foam molding introduces a blowing agent into materials such as PVC, PE, or PS to create a microcellular structure. Almost all thermosetting and thermoplastic plastics can be foamed, making this an important plastic processing field.

Similar to making steamed buns: adding baking powder (blowing agent) causes the dough (material) to expand with gas bubbles during heating. In plastics, gas injection can also replace chemical foaming.

8. Filament Winding Process

This technique wraps continuous fibers (or prepregs, tapes) impregnated with resin around a mandrel according to a specific pattern. After curing and demolding, the final product is obtained.