Classification & Application of Water-Based Release Agents in China

The Green Shift in Manufacturing: Driven by the imperative for "Green Manufacturing" and the "Dual Carbon" (Peak Carbon & Carbon Neutrality) goals, China’s manufacturing sector is rapidly transitioning from solvent-based oil release agents to Water-Based Release Agents. The stringent policy limitations on Volatile Organic Compounds (VOCs) have made "VOC elimination" an industry consensus. Concurrently, the increasing advantages of water-based systems in terms of safety, comprehensive performance, and total lifecycle cost are accelerating their shift from a "preferable option" to a "mainstream solution" across multiple industries. Compared to oil-based systems, water-based release agents utilize water as the carrier, significantly reducing VOC emissions and odor, thus improving the working environment. Their non-flammable nature effectively lowers the risk of fire and explosion, minimizing occupational health hazards. In terms of formulation, water-based systems can form a uniform, dense lubricating barrier film on the mold surface, achieving low demolding force and high surface quality. They also support high dilution ratios and convenient cleaning/maintenance, which helps reduce material consumption and overall operational costs, balancing production efficiency with sustainability goals. YunZhu New Material has specialized in water-based release agents for years. In the subsequent sections, we will delve into the classification system and major application scenarios of water-based release agents in China. Let's redefine the application of water-based release agents for "Made in China."

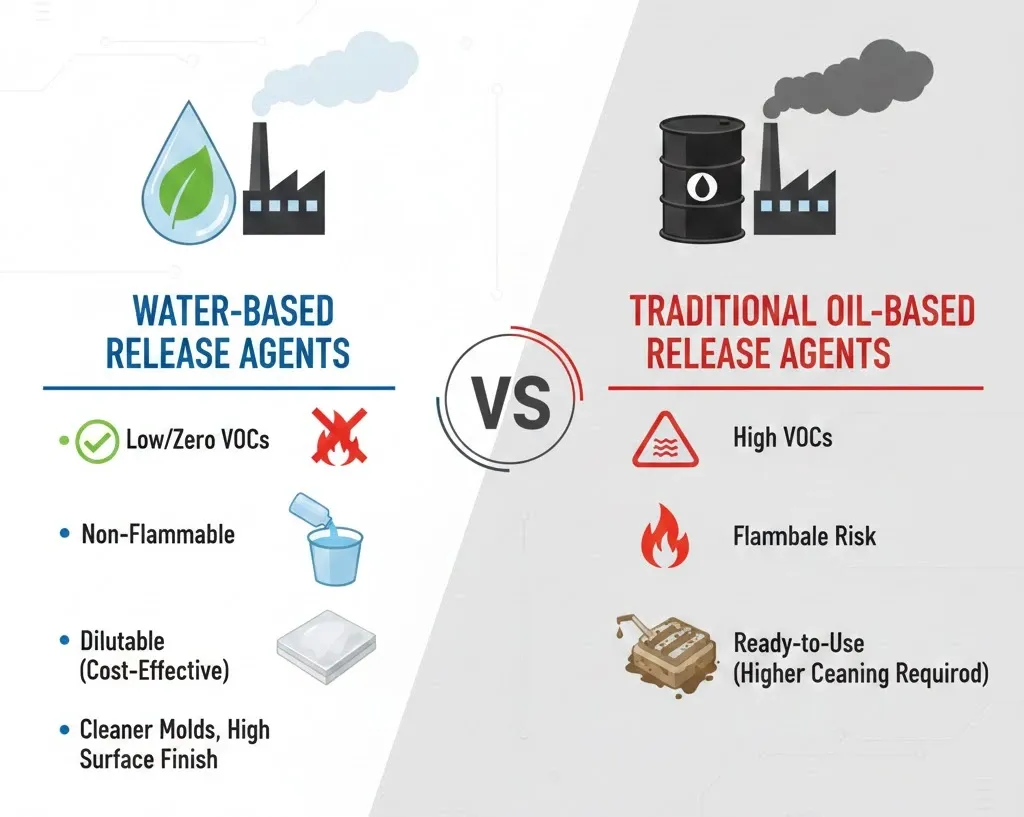

Part 1: The Debate – Water-Based vs. Traditional Oil-Based Release Agents

[Image: Water-Based Release Agent VS Traditional Oil-Based Release Agent Comparison Diagram]

Based on practical case studies and our customers’ pain points, both water-based and oil-based release agents possess their unique advantages. For instance, in concrete demolding applications, traditional oil-based release agents still hold a slight edge for complex mold geometries, high vertical formwork, and scenarios requiring rapid drying. However, with advancements in technology, improved oil-based release agents can now significantly reduce VOC emissions and achieve relatively fast drying times.

For clarity, the “oil-based” discussed below refers to external release agents that do not use water as a carrier, primarily composed of oily substances such as mineral oils or synthetic oils.

So, what are the key differences between water-based release agents and traditional oil-based types? See the detailed comparison in the table below:

| Comparison Aspect | Water-Based Release Agent | Traditional Oil-Based Release Agent |

|---|---|---|

| Environmental Friendliness | Greatly reduces VOC emissions, complies with strict environmental protection laws | Contains organic solvents that volatilize, high VOC emissions, pollutes the environment |

| Safety | Non-toxic, odorless, non-flammable, no oil mist/smoke/dust, safer to operate | Solvents are volatile and flammable, generate oil mist and black smoke, pose risks to health and safety |

| Demolding Effect | Uniform coating, good lubricity, can improve product surface quality | Mature film formation, but easily leaves oil residue, which may affect the product surface and secondary processing |

| Cost and Efficiency | High dilution ratio, low consumption; easy to clean, reduces downtime | Low unit price but requires frequent re-coating and cleaning, high long-term maintenance costs |

| Industry Adaptability | Suitable for modern equipment such as aluminum alloy forms, composite material molds; friendly to automatic spraying | Mainly used for traditional processes like steel forms and wooden forms; poor adaptability to new materials |

Part 2: Classification of Water-Based Release Agents

Following years of continuous iteration in formulation and technology, water-based release agents have evolved from early, singular emulsion systems into diverse, active-ingredient-centric systems. The mainstream types can be primarily categorized into four major classes: Silicone Oil Type, Wax Type, Fatty Acid Type, and Polymer Type.

These categories offer differentiated advantages concerning film formation and lubrication, surface finish quality, compatibility with subsequent processing, and cost.

2.1 Silicone Oil Type Water-Based Release Agents

These are typically non-ionic emulsions of high molecular weight silicone oils (such as Polydimethylsiloxane, PDMS) in water. The advantage of the non-ionic stabilization system is its ability to minimize sensitivity to the hardness of process water and other ions in the production environment, ensuring long-term emulsion stability.

From a performance perspective, silicone oil emulsions offer excellent thermal stability, superior lubricity, and film durability. These characteristics make them the preferred choice for applications subjected to high temperatures and high friction, such as release agents in the production of industrial rubber products and tires. Specific silicone emulsions designed for industrial rubber extrusion can have active ingredient viscosities as high as $1600 \text{ cSt}$. This high viscosity is crucial for forming a robust and durable barrier film under severe processing conditions.

2.2 Wax Emulsion Type Water-Based Release Agents

Wax emulsions are dispersions of natural waxes (such as Carnauba wax) or synthetic waxes (such as polyethylene or polypropylene waxes) in water. They primarily function by forming a physical barrier layer (often sacrificial) that provides good hydrophobicity. In large-scale, non-temperature-critical applications, such as concrete forming, wax emulsions are favored for their cost-effectiveness and efficacy.

2.3 Fatty Acid Type Water-Based Release Agents

Fatty acid type release agents are typically anionic or non-ionic. They are formed by dispersing the neutralized reaction product of fatty acids with alkali metals (such as sodium, potassium) or organic amines in water. The advantage of the anionic or non-ionic system is that it provides excellent emulsifying stability and good wettability.

Performance-wise, fatty acid release agents boast good water solubility and biodegradability. Their main components provide good lubrication and an effective isolation layer. These characteristics make them a common choice in applications where environmental friendliness and post-cleaning requirements are high, such as in the rubber, plastics, polyurethane foam, and die-casting industries.

2.4 Polymer Dispersion Type Water-Based Release Agents

Polymer dispersion release agents typically refer to emulsions where various high molecular weight polymers (such as Polyethylene, Polytetrafluoroethylene (PTFE), Polyether Ether Ketone (PEEK), etc.) are stably dispersed as fine particles in an aqueous phase.

The advantage of this system lies in the polymer’s inherent chemical inertness and high melting point, allowing it to form a barrier film with extremely high heat resistance and superior physical properties. A key strength is their ability to often provide semi-permanent release characteristics.

From a performance standpoint, polymer dispersions exhibit outstanding high-temperature resistance, chemical resistance, and durability, making them particularly suitable for aerospace composites, carbon fiber prepregs, and precision ceramic sintering.

Applications of the Four Water-Based Release Agent Types

| Release Agent Type | Core Application Orientation | Feature Summary |

|---|---|---|

| Silicone Oil Emulsions | Precision Parts, Rubber Tires | Low Demolding Force, High Surface Gloss, Excellent Thermal Stability |

| Wax Emulsions | Polyurethane Foam, Frequent Mold Opening and Closing | Strong and Abrasion-Resistant Film Formation, Suitable for Multiple Demoldings |

| Fatty Acids | Hard/Soft Foam Products | Cost Advantage, Friendly to Foam System |

| Polymer Type | Composite Materials, Special Plastics | Customizable Film Formation and Stability, Suitable for High-End/Complex Scenarios |

Part 3: Application Scenarios of Water-Based Release Agents

Water-based release agents are progressively replacing traditional oil-based counterparts across various industries due to their environmental friendliness (low VOCs), safety, and adaptability to modern manufacturing processes.

3.1 Automotive Interior & Seat Foams

- 3.1.1 Application Type: Primarily targets the release requirements for Polyurethane (PU) foams.

- 3.1.2 Advantages: Optimized water-based systems have achieved continuous mass production verification, effectively leading to cost reductions ranging from 8% to 35% by solving issues like shrinkage and sticking caused by traditional oil-based products in low temperatures.

- 3.1.3 Notes: Requires strict control over water ratio and spray volume, ensuring sufficient mold drying time. Attention must also be paid to odor, VOC levels, and powder feeding speed.

3.2 Construction Formwork

- 3.2.1 Application Type: Used to form an isolation film on the surface of formwork, facilitating demolding and protecting the mold.

- 3.2.2 Advantages: Significantly reduces concrete adhesion and blowholes, enhancing surface finish quality. For steel formwork systems, pretreatment can increase the demolding cycle count from 5 to 12 times.

- 3.2.3 Notes: The coating must be uniform and fully dried before pouring concrete to avoid runs, smudges, or localized whitening.

[Image: Construction Formwork and Concrete Demolding using Water-Based Release Agent]

3.3 Home Appliances/Electronics & Toy Injection Molding

- 3.3.1 Application Type: Targets exterior parts, precision components, and toy injection molded parts that demand high purity and low residue.

- 3.3.2 Advantages: Water-based systems meet the requirements for aesthetics and subsequent assembly, reducing odor and VOCs. Silicone oil emulsion types are the typical choice for precision parts due to their low demolding force and high surface finish.

- 3.3.3 Notes: Control the dilution ratio and the spray gun pressure/distance to prevent water stains or dripping. If necessary, use small samples for comparison to verify appearance and assembly compatibility.

[Image: Injection Molding Process for Small Electronic Parts or Toys with Release Agent]

3.4 Rubber/Composites & Die Casting

- 3.4.1 Application Type: Covers high-temperature, high-friction processes such as rubber vulcanization, composite material molding, and metal die casting.

- 3.4.2 Advantages:

- Silicone Oil Emulsion Type: Preferred for industrial rubber products and tire manufacturing due to outstanding thermal stability and film durability.

- Polymer Type: Adaptable to high-end scenarios like composites due to customizable film formation and stability.

- Water-Based Systems: Offer advantages in safety and environmental protection for high-temperature/high-pressure applications like Metal Die Casting.

- 3.4.3 Notes: Prioritize small-scale verification before scaling up production, paying close attention to mold sticking and the frequency of shutdown for cleaning.

[Image: High-Temperature Metal Die Casting or Rubber Vulcanization Process with Water-Based Release Agent]

Conclusion: Redefining Sustainable Manufacturing

The shift from oil-based to water-based release agents is more than just a regulatory response; it represents a fundamental commitment to sustainable and high-efficiency manufacturing in China.

Water-based systems, characterized by low VOCs, enhanced safety, and superior demolding performance, are no longer limited to niche applications but have become a core strategic pillar across high-end industries—from automotive interiors and precision electronics to advanced composites and metal forming.

The four major categories—Silicone Oil, Wax, Fatty Acid, and Polymer types—provide manufacturers with a diverse toolkit to precisely match performance requirements (such as thermal stability, release force, and post-processing compatibility) with sustainability goals.

YunZhu New Material is committed to driving this green transition. By continuously optimizing water-based formulations, we ensure that the “Made in China” label continues to embody both manufacturing excellence and environmental responsibility.

Embrace the future of demolding technology—choose high-performance, water-based solutions for a safer and more sustainable operational lifecycle.

Marco Zhang

Co-founder & Product Engineer at Yunzhu

Identifying the right release agent shouldn't be a gamble. With 7+ years in chemical engineering, I help manufacturers in Concrete, PU, and Composites industries eliminate air bubbles and sticking issues. At Yunzhu New Materials, we don't just sell chemicals; we provide demolding solutions. We specialize in: 1.Water-based Concrete Release Agents (Eco-friendly & High Gloss) 2.Carbon Fiber & Composite Solutions 3.Custom formulation for specific temperature/mold requirements I bridge the gap between Chinese manufacturing efficiency and global quality standards. Whether you need a free sample test or technical advice on mold maintenance, feel free to reach out.

View LinkedIn Profile