Evolution of Formwork Release Agent Processes and Market Competitiveness

Before steel bars and concrete constructed the framework of modern China, there was a critical yet often overlooked step in the concrete construction process: demolding. The practice began with basic, experience-driven methods, such as applying a layer of waste engine oil or simple soap solution. Today, the technology has undergone a significant transformation. The shift to water-based series has become mainstream. The application of bio-based raw materials, biodegradable surfactants, and nano-modification technologies is driving the next level of upgrade in China's release agent manufacturing. This push has led to the widespread adoption of green, eco-friendly, and high-performance concrete release agents in China, enabling domestic enterprises to establish strong competitiveness against established global brands.

1. A Brief History of Concrete Release Agent Development in China

1.1 Early Exploration Period (1950s–1970s)

During the 1950s and 60s, as large-scale infrastructure construction began, the initial makeshift solution—a combination of waste engine oil and soap solution—quickly revealed its shortcomings. These drawbacks included template contamination, compromised concrete appearance, and interference with subsequent coating applications. Consequently, the industry consciously started seeking more stable materials. Some factories began experimenting with modifying animal and vegetable oils or incorporating small amounts of mineral oil and emulsifiers to self-produce emulsified release agents. Although stability remained limited, this marked a significant step forward at the time.

1.2 Improved Transition Period (1980s)

The 1980s saw the beginning of synthetic chemical technology development in China. Release agent formulations started incorporating components like fatty acid soaps and paraffin emulsions. Furthermore, the emulsification process advanced from manual stirring to mechanical homogenization. Products from this phase showed clear improvements in demolding performance, increased template turnover, and enhanced quality of the component surface. However, issues persisted: some products had strong odors, others separated and failed in high-temperature seasons, and some residues adversely affected concrete strength. This was a period of trial-and-error, where R&D personnel tackled a complex, multi-variable equation.

1.3 Technological Maturation Period (1990s)

Entering the 1990s, the dual drivers of the market economy and technological imports brought mature water-based release agent formulations and preparation concepts from abroad into view. Domestic enterprises began systematic research into interface chemistry and emulsion stability mechanisms. Materials like polycarboxylates, high-molecular polymers, and organosilicon-modified agents were successively introduced.

On the processing side, crude mixing was replaced by high-pressure homogenization, precise temperature control, and multi-layer filtration. This resulted in more uniform particle size distribution and product stability across different seasons and regions. At this stage, the release agents did not just effectively isolate concrete from the formwork; they also balanced environmental protection and construction convenience, featuring low odor, easy cleaning, and non-corrosion to steel reinforcement. They became a standard auxiliary material for major bridges, tunnels, and high-rise buildings.

1.4 Modern Advanced Stage (2000s–Present)

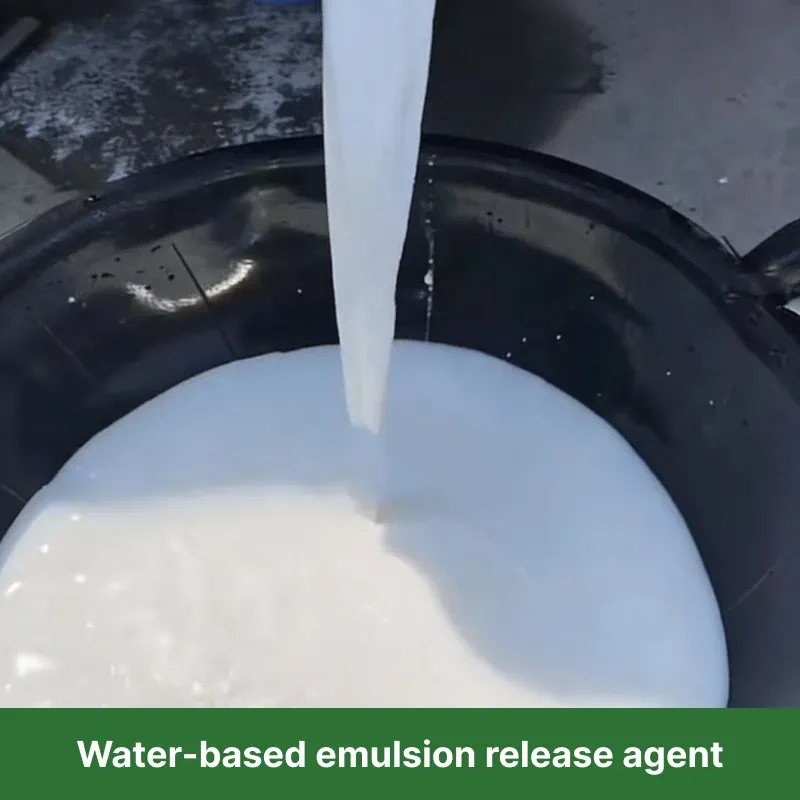

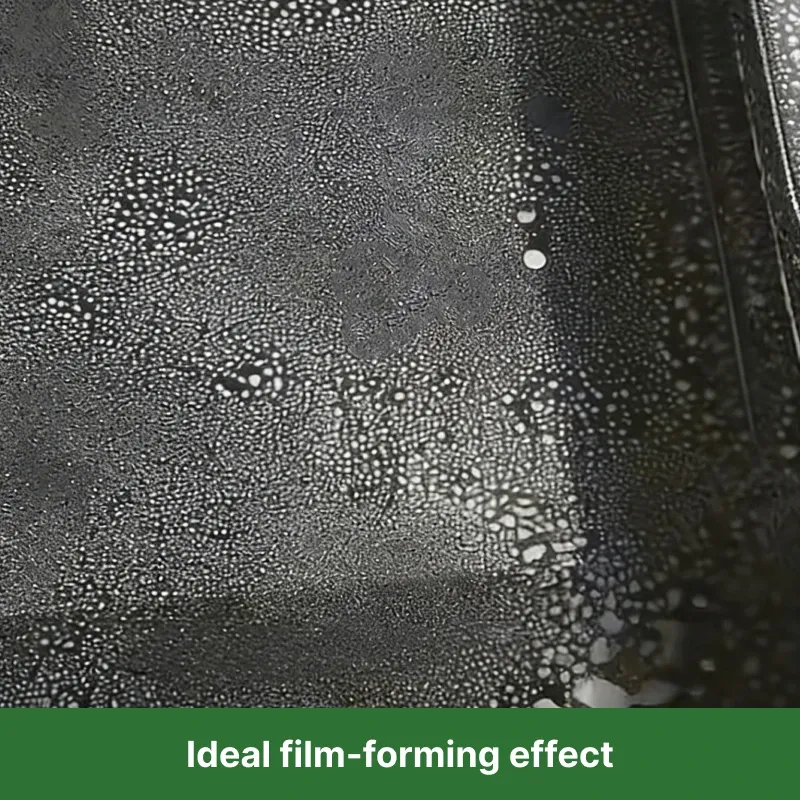

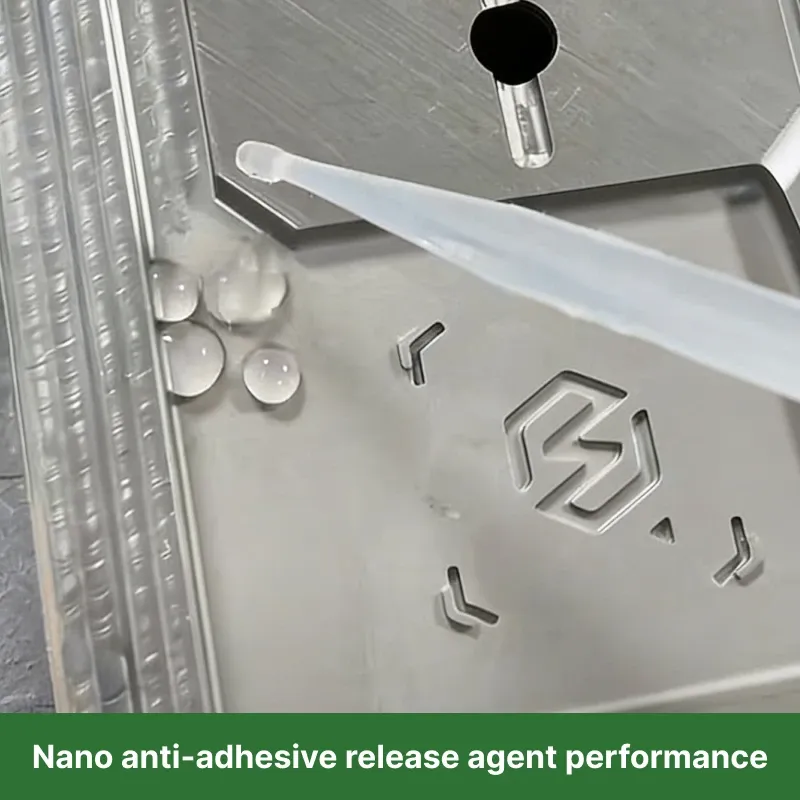

The first two decades of the 21st century have seen the convergence of green manufacturing and high-performance demands, pushing release agent technology to a new level. The water-based system has become dominant. Bio-based raw materials and biodegradable surfactants have begun to replace petroleum-derived components. Nano-modification technology ensures a more uniform film formation and more durable isolation.

Functionalized design allows a single product to be compatible with various materials, including steel, timber, and plastic molds. Furthermore, some enterprises have introduced intelligent production into formulation debugging and quality control, enabling real-time monitoring of viscosity, pH value, and solid content. This transformation has replaced the reliance on “master craftsman’s feel” with traceable, data-driven processes.

| Development Stage | Time Period | Technical Features | Material/Process Progress | Issues |

|---|---|---|---|---|

| Early Exploration | 1950s–1960s | Industry begins using basic release materials | Engine oil + soap water; early attempts with vegetable/animal oils, mineral oil + emulsifiers | Template pollution, poor appearance, coating interference; low stability |

| Improvement Transition | 1970s–1980s | Chemical industry begins; formula-based release agents emerge | Fatty acid soaps, paraffin emulsions; mechanical homogenization; better release performance | Odor, high-temperature separation, residue affecting strength |

| Technical Formation | 1990s | Market & technology import drive maturity | Imported water-based concepts; polymer, organosilicon; high-pressure homogenization, temperature control, multi-stage filtration | Higher cost & complexity, but performance reliable |

| Modern Advanced Stage | 2000s–2020 | Green & high-performance needs lead to upgrades | Water-based mainstream; bio-based raw materials; degradable surfactants; nano-modification; intelligent production | Higher technical requirements |

2. The Influence of Different Process Routes on Concrete Surface Quality

Currently, the mainstream technologies for concrete release agents in China primarily include Oil-based/Solvent Type, Water-based Emulsion Type, Template Paint/Resin Type, and Oleate Active Systems. These different process routes are widely applied in modern construction.

2.1 Process Routes and Adaptation Scenarios

-

Oil-based/Solvent Type: This type uses mineral oils, vegetable/animal oils, or solvents as the carrier. It forms a thin film and migrates quickly, offering low initial cost. However, it is prone to issues such as odor, high VOCs, and surface air bubble absorption, leading to greater variability in surface appearance consistency.

-

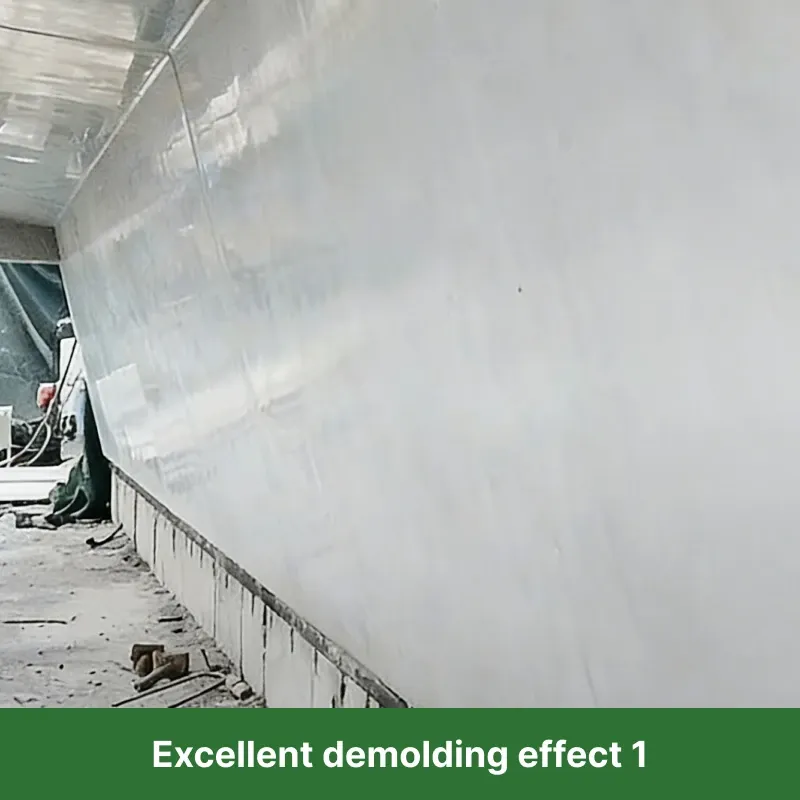

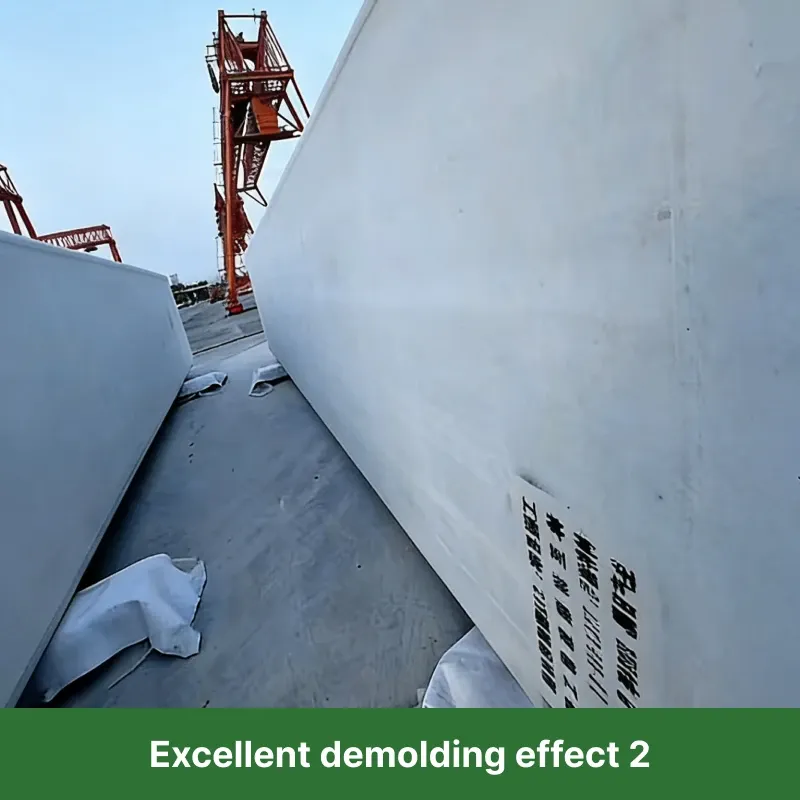

Water-based Emulsion Type: Using water as the continuous phase, this type is combined with surfactants/emulsifiers to form a stable microemulsion. It features low odor, low VOCs, and uniform film formation, which helps in releasing interface air bubbles. It is suitable for most scenarios, including aluminum and steel molds.

-

Template Paint/Resin Type: This route involves forming a hard paint film on the formwork surface, allowing for multiple reuse cycles. However, it demands high construction cleanliness and film uniformity. Improper application can easily lead to localized sticking to the mold, color differences, and pitting (pocked surfaces).

-

Oleate Active System: This system is centered around oleate esters combined with fatty amine polyoxyethylene ethers/esters. It offers a combination of wetting, diffusion, and rust inhibition. It is well-suited for steel molds and steam curing conditions. Actual measurements show it can reduce the adhesion of concrete to the formwork to approximately 1.1–1.5 g/m².

2.2 Comparison of Key Metrics

| Process | Advantages | Risks | Key Application Points |

|---|---|---|---|

| Water-based Emulsion Type | Low odor, low VOC, uniform film formation, beneficial for bubble release | Construction affected by humidity/temperature, spraying is prone to local defects | Recommended for brushing or uniform spraying; Water-based is prioritized for aluminum molds |

| Oil-based/Solvent Type | Fast migration, strong short-term demolding force | Prone to air bubble absorption, dull surface, high VOC, difficult mold cleaning | Only for transition or specific working conditions, strict control of dosage and cleaning is required |

| Template Paint/Resin Type | Reusable for multiple cycles, smooth surface | Complex construction, prone to localized bubble accumulation/color difference | Molds require high cleanliness and complex specifications, suitable for high-quality fair-faced concrete |

| Oleate Active System | Steel mold friendly, rust inhibition, low adhesion | Requires shear preparation at 65-75°C, narrow process window | Preferred for precast components, steam curing, and steel mold systems |

3. Competitiveness of Chinese Concrete Release Agents

3.1 Market Landscape of Concrete Release Agents

The global market for precast concrete release agents remains highly prosperous, with its scale projected to reach USD 20.642 billion by 2029. The sector has attracted multinational giants such as Sika, BASF, Mapei, Fuchs, Evonik, Shin-Etsu, GCP, WR Meadows, Doka, Nox-Crete, Kao, and Croda.

In the Chinese market, driven by the “Dual Carbon” goals and the promotion of green building materials, the share of water-based and environmentally friendly products is increasing from 37% to over 55%+. The adoption rate of products with a VOC≤80 g/L in key engineering projects exceeds 90%.

Chinese concrete release agent manufacturers are standing out due to their advanced technology, excellent product performance, and cost advantages. They exhibit superior cost-effectiveness (value-for-money) and service advantages in the mid-to-high-end markets. Their level of high-end and systematic solutions is also gradually catching up with that of major global brands.

3.2 Technology and Product Capability

The advantage of major global brands lies in a closed-loop system of “Chemical Platform + Engineering Service” that spans multiple materials and scenarios. For example, Nox-Crete FormCoating has employed a chemically active route since 1956. It reacts immediately upon contact with fresh concrete, providing demolding, waterproofing, anti-rust, and extended formwork life. It offers low-emission versions (VOC≤250 g/L) and a diverse product range (water-based/concentrated/biodegradable), compatible with various formwork types like wood, steel, aluminum, and plastic, meeting high standards for surface appearance and high-cycle turnover.

In the past five years, Chinese local technology has rapidly developed characteristics of "Water-based, Functional, and Stable”:

- On one hand, mainstream processes have emerged, including eco-friendly water-based emulsions, nano-modification, and adaptability for intelligent construction.

- On the other hand, continuous innovation is seen in areas like W/O (Water-in-Oil) emulsification and reactive composites, balancing film-formation with demolding, and reducing oil content and residue risk.

3.3 Comparison of Key Parameters

| Dimension | Global Brands (Sika/BASF/Mapei/Nox-Crete, etc.) | Local Chinese Company |

|---|---|---|

| Technical Route | Organosilicon/Polymer platform + chemically active system, covers oil/water/reactive and formwork paint | Water-based emulsion as the origin, W/O emulsification, reactive and functional compounds advancing simultaneously |

| Product Range | Full-scenario coverage, low VOC/biodegradable/high-modulus multi-type range | Complete product range, high cost performance, adapted to local engineering conditions |

| Appearance & Bubble Control | Stable clear water/simple texture appearance, mature management of formwork scaling and cleaning cycles | Significant improvement in water-based system appearance and bubble control, suitable for aluminum/steel molds |

| Multiple Cycles & Rust Prevention | Mature formwork life and anti-rust system, thoroughly validated across climates | Rapid improvement in steel mold rust prevention and turnaround performance, strengthening long-term data accumulation |

| Compliance & Sustainability | Early deployment in VOC regulations, odor control, sustainability, and biodegradability | Rapid increase in VOC and environmental protection driven by “Dual Carbon” goals |

| Engineering & Service | Global engineering validation + application engineering + training closed-loop | Fast local response, high efficiency in customization and delivery |

| Cost & Delivery | Higher overall cost and compliance premium | Clear advantages in total life cycle cost, fast response with regional warehousing |

4. Summary

Chinese concrete release agents have evolved significantly from the early era of using waste engine oil, progressing through four stages: exploration, improvement, technical maturity, and modern sophistication. With the widespread application of water-based systems, bio-based raw materials, biodegradable surfactants, nanotechnology, and smart manufacturing, the environmental friendliness, stability, and adaptability of Chinese release agents have improved substantially.

In competition with major global brands, Chinese enterprises stand out in the mid-to-high-end markets by leveraging water-based and eco-friendly processes, stable appearance control capabilities, rapid response times, and cost advantages. They are continuously catching up with—and in some areas, even locally surpassing—international brands in directions such as functional composites, low VOC, and multi-scenario adaptability, demonstrating strong industrial upgrading and competitiveness.

Marco Zhang

Co-founder & Product Engineer at Yunzhu

Identifying the right release agent shouldn't be a gamble. With 7+ years in chemical engineering, I help manufacturers in Concrete, PU, and Composites industries eliminate air bubbles and sticking issues. At Yunzhu New Materials, we don't just sell chemicals; we provide demolding solutions. We specialize in: 1.Water-based Concrete Release Agents (Eco-friendly & High Gloss) 2.Carbon Fiber & Composite Solutions 3.Custom formulation for specific temperature/mold requirements I bridge the gap between Chinese manufacturing efficiency and global quality standards. Whether you need a free sample test or technical advice on mold maintenance, feel free to reach out.

View LinkedIn Profile