A Practical Step-by-Step Guide: How to Identify a Reliable and Suitable Release Agent Supplier in China

In the release agent industry—although highly specialized—it plays a critical role in determining product quality and production stability. Choosing a reliable and suitable release agent supplier in China is often far more important than simply comparing prices. With a large number of manufacturers in the market and significant differences in technical capability and consistency, many purchasing managers face the same questions: - How can you tell whether a supplier truly has technical expertise? - Can they provide stable and consistent supply? - Are their products genuinely suitable for your specific application? Based on real industry experience, this article examines common challenges and practical requirements from key perspectives, including certifications, product suitability, technical support, and delivery capability. It provides a clear framework to help you quickly identify trustworthy, long-term Chinese release agent suppliers, reduce trial-and-error costs, and improve overall production efficiency.

1. Choosing the Wrong Release Agent Supplier Can Cost More

In the overall cost structure, release agents usually account for only a small percentage. However, selecting the wrong supplier can trigger a series of costly issues, such as:

- Color inconsistency, air bubbles, or surface defects on concrete products

- Poor demolding performance in composite materials, leading to rework and scrap

- Severe mold contamination, increasing cleaning frequency and maintenance costs

- Inconsistent product quality between batches, forcing frequent process adjustments

For professional buyers, long-term stability and consistency are far more important than unit price.

2. Understanding the Industrial Distribution of Release Agent Manufacturing in China

To identify a suitable release agent supplier, it is essential to first understand how the release agent industry is distributed across China.

2.1 Overall Industrial Distribution in China

China’s release agent industry follows a clear pattern: strong concentration in eastern and southern coastal regions, with gradual expansion toward central and western areas.

East China and South China together account for approximately 60–70% of national production and consumption. Among them, Guangdong, Jiangsu, and Zhejiang provinces benefit from well-developed chemical industries and downstream manufacturing clusters. Each of these provinces records an estimated annual procurement volume exceeding RMB 800 million, making them core industrial hubs.

2.2 Regional and City-Level Concentration

From a city-level perspective, the industry shows high concentration in major manufacturing and commercial centers:

- Shanghai: ~16.7%

- Guangzhou: ~8.3%

At the provincial level:

- Guangdong: ~33.3%

- Shandong: ~25.0%

Enterprise registration data further confirms this clustering trend:

- Shanghai: ~21.9%

- Dongguan: ~12.1%

- Guangzhou: ~10.7%

By province:

- Guangdong: ~32.2%

- Shanghai: ~20.2%

- Jiangsu: ~12.0%

These figures reflect a strong concentration in coastal manufacturing centers and economically developed provinces.

As a result, starting supplier screening in regions with high industrial concentration is a practical and efficient first step, significantly increasing the likelihood of identifying reliable and qualified Chinese release agent manufacturers.

3. Distinguishing Between Trading Companies and Manufacturers

Both trading companies and manufacturers have their respective roles and advantages.

Trading companies often act as a bridge between factories and overseas customers, providing communication, coordination, and service support. Manufacturers, on the other hand, typically have advantages in product quality control, production management, and the ability to offer customized solutions based on specific applications.

Therefore, the second key step in selecting a Chinese release agent supplier is to clearly understand the supplier’s actual role.

When evaluating a potential supplier, consider the following points:

- Do they own their own production facilities and equipment?

- Can they clearly explain the basic formulation system and working principles of their products?

- Do they have the capability to ensure batch-to-batch consistency?

- Are they simply representing or reselling multiple brands without manufacturing involvement?

A true manufacturing-based supplier usually offers more than just product delivery. They are better positioned to support product optimization, root-cause analysis, and long-term technical cooperation, which is especially important for application-driven industries such as concrete, composites, PU, and rubber processing.

4. Define Your Requirements Clearly to Select the Right Supplier with Purpose

Before evaluating any supplier, buyers must first have a clear and structured understanding of their own requirements. Without this, it is difficult to communicate effectively or assess whether a supplier is truly suitable.

Key aspects to define include:

- Process and application: Clearly identify the application scenario, such as polyurethane (PU), rubber, composite materials, injection molding of thermoplastics, or die casting / metal casting.

- Mold and substrate type: Steel molds, aluminum molds, silicone molds, or other specific substrates.

- Formulation preferences: Common release agent systems include silicone-based, wax/oil-based, fluoropolymer-based, surfactant/soap-based, and inorganic systems (such as talc or mica). Each formulation has its appropriate applications.

- Regulatory and EHS requirements: Water-based or low-VOC systems are increasingly preferred to meet environmental, health, and safety standards.

- Additional performance requirements: Expected number of release cycles, surface finish (high gloss, matte, no transfer), and compatibility with secondary processes such as painting, bonding, or electroplating.

Only when requirements are clearly defined can buyers communicate efficiently with suppliers and accurately identify a Chinese release agent supplier that truly matches their application needs.

5. Technical Evaluation and Sample Testing

After shortlisting several potential suppliers, the next step is a structured technical evaluation.

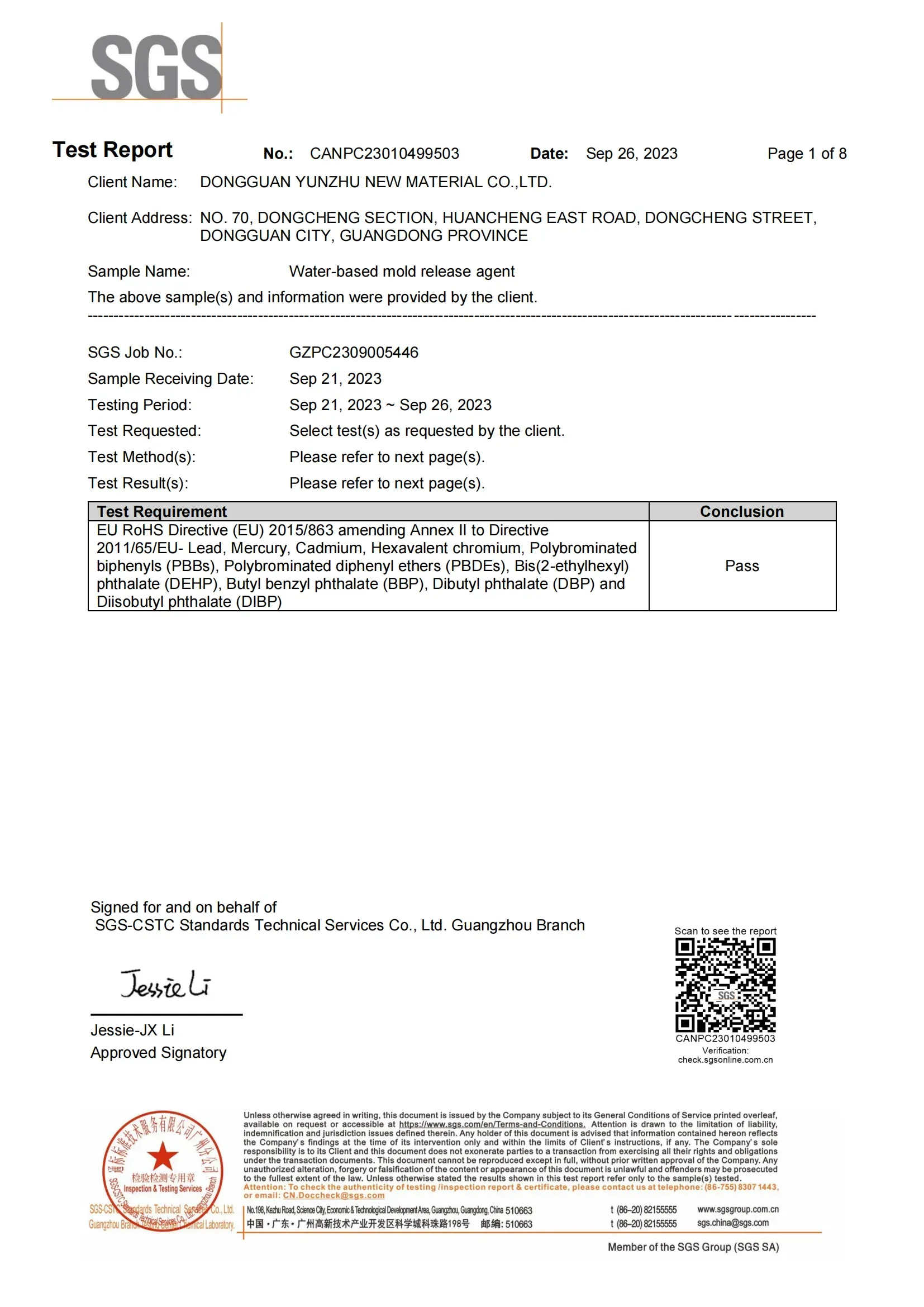

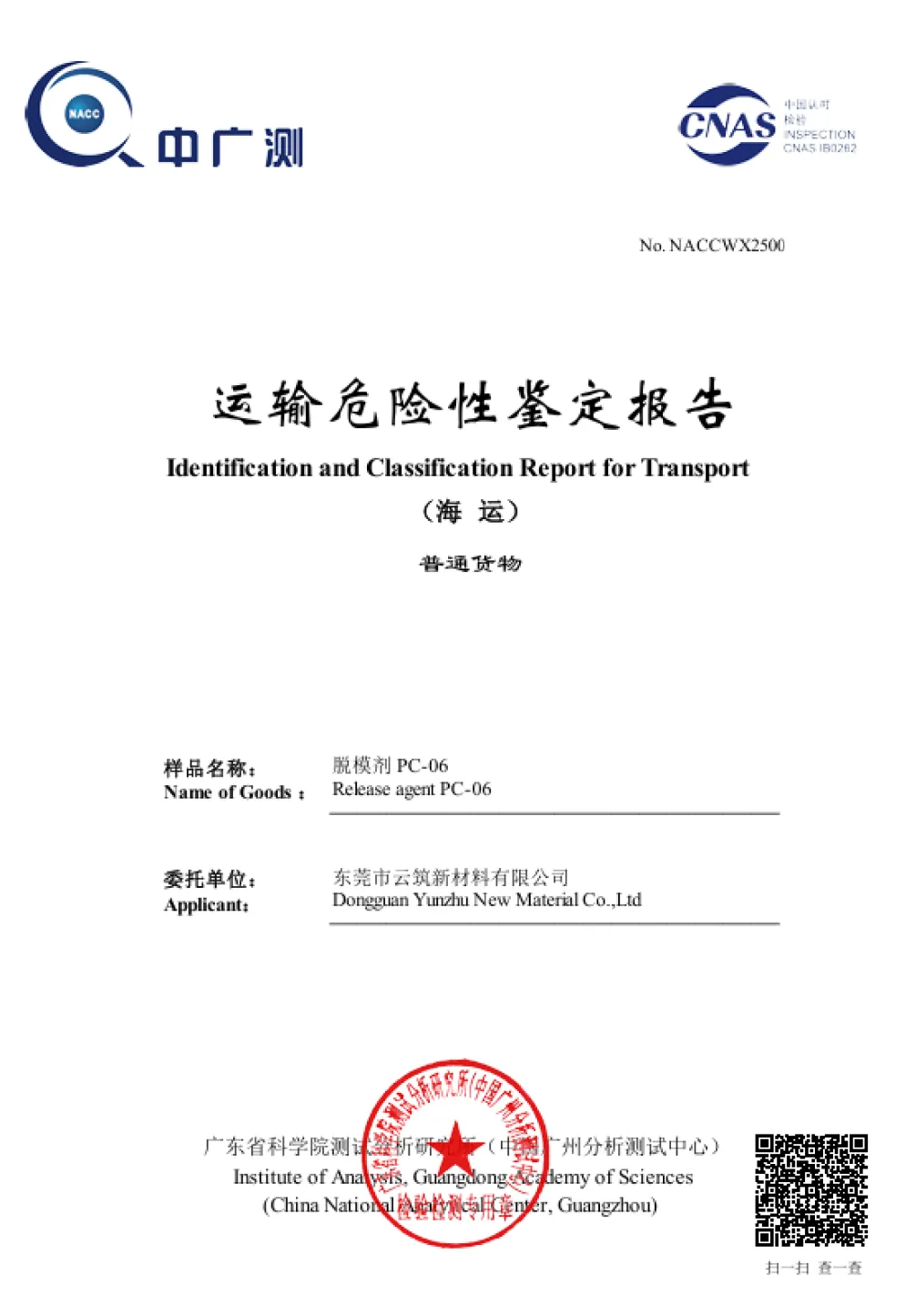

Buyers should collect and review information from official websites, product brochures, and test reports. It is also important to verify key documents such as business licenses, hazardous chemical permits (if applicable), SDS, and compliance documents including REACH, RoHS, and FDA (for food-contact applications). Suppliers with incomplete certifications or unclear information should be eliminated at this stage.

Technical documents such as MSDS and TDS are critical references when assessing a supplier’s professionalism. However, higher or more aggressive specifications do not necessarily mean better performance. Key points to review include:

- Whether the documentation is complete and logically consistent

- Whether recommended dilution ratios and application rates align with practical industry experience

- Whether the supplier can clearly explain solid content, film-forming mechanisms, and other key parameters

- Whether the stated performance parameters are appropriate for the intended application

Reliable suppliers are usually able to explain why a product is designed in a certain way, rather than simply presenting a set of numbers.

After technical evaluation, buyers should proceed with small-scale sample testing, carefully documenting performance results. This step provides essential data to support confident decisions before moving to larger-volume procurement.

6. Evaluate the Manufacturer’s Problem-Solving Capability

Beyond selecting a suitable release agent product, application-related issues are common in real production environments. Typical challenges include material transfer, sticking to molds, uneven surface appearance, severe mold buildup, and reduced adhesion in subsequent processes such as painting or bonding.

Therefore, it is essential to evaluate whether a release agent manufacturer has advanced problem-solving capabilities, rather than simply supplying products.

Suppliers truly worth long-term cooperation usually demonstrate the following strengths:

- They can provide adjustment recommendations based on specific process conditions, rather than generic advice

- They support sample testing and phased validation, allowing performance to be verified step by step

- They are willing to continuously follow up on trial results and application feedback, instead of focusing solely on one-time product sales

In B2B industrial applications, release agents should be viewed as technical solutions, not commodity items. A manufacturer’s ability to analyze problems and optimize performance is often the key factor in achieving stable, long-term production results.

7. Assess Production Capacity, Lead Time, Contracts, and Logistics

Once the product and supplier have been technically validated, the final step is to confirm commercial and operational details.

In most cases, it is recommended to establish a framework agreement covering key terms such as lead time, minimum order quantity (MOQ), quality KPIs, and clearly defined boundaries for returns or claims. During this stage, buyers should pay particular attention to the following aspects:

- Supply stability: Whether the supplier has the capacity to support long-term delivery with consistent quality

- Export and packaging experience: Whether they are familiar with international shipping, labeling requirements, and export documentation

Careful evaluation of these factors helps ensure smooth execution after order placement and reduces operational risks in long-term cooperation.

Conclusion: Choosing the Right Supplier is a Long-Term Value Decision

When selecting a Chinese release agent supplier, instead of chasing “lowest price or everything offered,” focus on a partner who:

- Truly understands your industry and specific applications

- Has strong manufacturing and technical support capabilities

- Values long-term cooperation and consistent performance

A systematic evaluation helps you find a reliable, suitable, and sustainable release agent supplier, ensuring product quality and project success.

Marco Zhang

Co-founder & Product Engineer at Yunzhu

Identifying the right release agent shouldn't be a gamble. With 7+ years in chemical engineering, I help manufacturers in Concrete, PU, and Composites industries eliminate air bubbles and sticking issues. At Yunzhu New Materials, we don't just sell chemicals; we provide demolding solutions. We specialize in: 1.Water-based Concrete Release Agents (Eco-friendly & High Gloss) 2.Carbon Fiber & Composite Solutions 3.Custom formulation for specific temperature/mold requirements I bridge the gap between Chinese manufacturing efficiency and global quality standards. Whether you need a free sample test or technical advice on mold maintenance, feel free to reach out.

View LinkedIn Profile