Key Points – SOP for Water-Based Concrete Release Agents

With years of experience in developing and applying concrete release agents, our company has created a standardized SOP for using water-based concrete release agents. This guide helps ensure high-quality concrete surface finishes and extends mold life.

Link## 1. Mechanism and Conditions for Using Water-Based Release Agents

1.1 Mechanism of Water-Based Release Agents

Water-based concrete release agents use water as the main medium, dispersing emulsified oils, surfactants, or reactive substances to form an emulsion. Their working principles include physical isolation and chemical isolation.

- Physical isolation: A thin, dense, and continuous protective film forms on the mold surface, preventing direct contact between the concrete and the mold.

- Chemical isolation: Active substances in the release agent react with the mold surface or calcium ions in the concrete to form soluble or low-adhesion soap-like layers, enabling smooth demolding.

Our company’s water-based release agents achieve smooth demolding primarily through physical isolation.

1.2 Conditions for Using Water-Based Release Agents

The performance of water-based products is highly affected by environmental conditions, especially temperature.

When the ambient temperature is below the minimum operating range, the evaporation rate of water slows down significantly, preventing the release agent from forming a proper film within a reasonable time. If concrete is poured before film formation, the mixture may absorb the release agent, leading to adhesion failure.

Conversely, when the temperature exceeds the maximum operating limit, water evaporates too quickly, causing uneven coating and leaving residues of active substances on the mold surface. This not only reduces release performance but can also damage the concrete surface quality.

Water-based concrete release agents should be stored in a cool, dry, and shaded area. Our laboratory data show an effective working temperature range of 5–40°C. However, feedback from our northern clients indicates that the product can still perform reliably even at 0°C during winter.

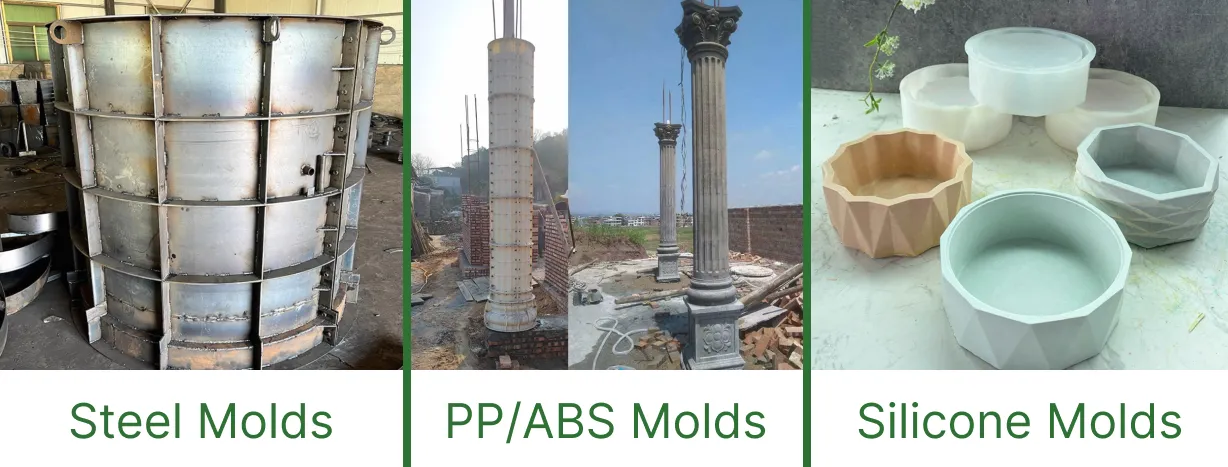

2. Compatibility Between Mold Materials and Release Agents

2.1 Steel Molds

Steel molds are the most compatible with our products. They have high surface energy, which generally provides good wettability for release agents. However, their main risk lies in oxidation and corrosion. When moisture from water-based release agents remains on the steel surface without proper anti-corrosion protection, it can easily cause rusting. Rust not only destroys the isolation layer formed by the release agent—leading to sticking—but can also cause iron ion contamination, leaving rust stains on the concrete surface.

Therefore, the pre-treatment of steel molds should focus on thorough rust removal and degreasing. After cleaning, the release agent should be applied immediately to achieve surface activation or passivation. The recommended dilution ratio is 3–6 times, ensuring sufficient active ingredient concentration for both corrosion resistance and release performance. The standard application rate is approximately 10–20 kg/m².

2.2 PP/ABS Molds

Polypropylene (PP) and acrylonitrile-butadiene-styrene (ABS) are low surface energy polymers, which makes it difficult for water-based release agents to spread evenly. This can result in “beading” on the surface, leading to an incomplete coating. Additionally, these plastic molds often have microporous surfaces.

For PP/ABS molds, avoid using strong solvents that may damage the plastic or leave residues during cleaning. When applying water-based release agents, the key step is sealing the micropores. It is recommended to apply a single thick coat at standard concentration or slightly lower, and ensure it is fully dry. This allows the active ingredients in the release agent to fill or cover the micropores, creating a stable, low-absorption interface.

2.3 Silicone Molds

Silicone molds have very low surface energy and excellent flexibility and self-release properties. In this case, the release agent mainly serves as micro-level auxiliary isolation to prevent fine bubbles from sticking and to improve the concrete surface finish.

The main risk with silicone molds is over-application of release agent. Excessive buildup can transfer to the concrete surface, affecting fine details or leaving residues. Pre-treatment typically requires only gentle cleaning to remove dust or concrete residue, and cleaners that could damage the silicone structure must be strictly avoided.

3. Standard Operating Procedure (SOP) for Water-Based Concrete Release Agents

Below, we use steel molds as an example to introduce the standard SOP for using water-based concrete release agents.

Step 1: Mold Cleaning – Remove Residues and Water Marks

1. Importance of Mold Cleaning Before demolding, all residues such as old concrete particles, grease, rust, or previous release agent layers must be thoroughly removed. Any leftover contaminants can break the continuity of the new coating, create stress concentration points, and lead to sticking or surface defects during demolding, such as bubbles or rough spots on the concrete surface.

For water-based concrete release agents, mold cleanliness is a critical control point. The mold surface must be visibly clean before proceeding to the next coating step.

2. Quality of Mold Joint Sealing Based on our client cases, in addition to mold cleaning, the sealing of mold joints is another critical factor.

The quality of mold joint sealing is a key preventive measure against concrete defects. If the joints are not properly sealed, fine cement slurry can leak through gaps during pouring and vibration. This leakage can cause aggregate accumulation at edges and loss of cement paste, making the edge areas structurally weak.

Even if the main body of the concrete reaches the demolding strength, minor shear or tensile forces during demolding can cause cracks or serious defects at the edges. Therefore, it is essential to use sealing strips, tapes, or specialized sealants to ensure all joints remain tight under pouring pressure and vibration. Proper sealing is a prerequisite for maintaining both the appearance and structural integrity of the final product.

Step 2: Diluting the Release Agent

- Use clean tap water for dilution; groundwater should not be used. The quality of the dilution water directly affects the stability of the emulsion and the performance of the final coating. Hard water, containing high levels of calcium, magnesium, or other multivalent metal ions, can pose a significant risk when preparing water-based release agents. Therefore, it is important to regularly test the water’s pH and total hardness, and use softened or deionized water if necessary.

-

Correct Dilution Ratios The dilution ratio of release agents is not fixed and should be dynamically adjusted based on the mold material, environmental conditions, and concrete type.

- Environmental factors: In high humidity or low-temperature conditions, water evaporates slowly. Using a high dilution ratio in such cases will significantly extend drying time and affect production schedules. To ensure proper film formation, the dilution should be reduced to increase the concentration of active ingredients.

- Concrete type and curing method: For elements requiring steam curing or made with self-compacting high-performance concrete (HPC), the mold surface temperature can rise significantly. The release agent must have high thermal stability and durability. In such cases, the dilution ratio should be lowered to ensure the coating thickness and strength are sufficient to withstand high temperature and pressure.

- Preparation method: Release agents must be prepared in clean containers. Stirring should be thorough and uniform, but at low speed to prevent damaging the emulsion structure and causing phase separation.

For our water-based concrete release agents, laboratory tests and client experience show a dilution range of 3–25 times, depending on the specific product and mold. For first-time use, we recommend starting with a 3x dilution and adjusting based on demolding performance.

Step 3: Applying the Release Agent

Our water-based concrete release agents can be applied by spraying, brushing, or rolling. Based on client experience, combining spraying with manual application often produces remarkably uniform and effective results.

-

Use low-pressure spraying equipment. The goal is to achieve fine atomization, not water droplets or running liquid. Key parameters include spray pressure (recommended 0.1–0.3 MPa) and distance from nozzle to mold surface (usually 20–30 cm). Excessive application wastes material and creates a too-thick isolation film, which may cause oil stains or discoloration on the concrete surface. Insufficient application can result in discontinuous coverage, leading to localized sticking. After spraying, manually wipe the mold with a clean towel soaked in release agent to ensure even distribution and complete the application process.

-

Pay attention to drying time and environmental conditions. Water-based release agents must be fully dry before pouring concrete. Drying means that all moisture has evaporated and the active isolation film is fully formed and stable. If the concrete comes into contact with an undried coating, residual water may mix with the concrete, diluting or absorbing the active ingredients, causing coating failure and resulting in stickin

Step 4: Demolding – Successful Release

Demolding must be performed only after strict concrete strength verification. Before removing the mold, compressive strength tests should be conducted on test specimens cured under the same conditions, following standard regulations. Demolding is permitted only when the test results meet the preset minimum strength, which is generally 20 MPa for most applications.

Strength assessment must be statistically rigorous. Relevant standards emphasize that strength determination should consider the mean, standard deviation, and minimum value of representative concrete strength data. In practice, the lowest measured compressive strength should be used as the reference to ensure structural safety. Premature demolding due to insufficient strength is a major cause of internal cracks, surface damage, and safety incidents in concrete elements.

4. Conclusion: Cost Efficiency, Environmental Benefits, and Long-Term Maintenance

Water-based concrete release agents offer significant advantages in modern construction. Their very low VOC content greatly improves the working environment and health of on-site personnel, aligning with global trends toward green building and sustainability.

From an economic perspective, although the initial purchase cost may be higher than traditional oil-based products, strict process control, particularly precise coating application, ensures higher material utilization. More importantly, proper use of water-based release agents effectively protects mold surfaces, especially sensitive PP/ABS and silicone molds, extending their service life and reducing long-term overall costs.