Surface Air Bubbles in Precast Concrete: Causes and Solutions

A deep analysis of the mechanisms behind air bubble formation in precast concrete elements, with multiple strategies to prevent bubble occurrence. The focus is on the fact that selecting the right concrete release agent can effectively prevent air bubbles in concrete.

Introduction: The Hidden Technical Challenge Behind the Surface

As a core component of modern industrialized construction, precast concrete (PC) elements play a decisive role in determining both the aesthetic appeal and long-term durability of a structure.However, surface air bubbles—though seemingly minor—have long troubled the industry. They not only compromise the visual quality of concrete surfaces but also indicate potential issues with compaction and internal density, which may affect long-term performance.This article goes beyond a superficial description of the problem.From the combined perspectives of material science, chemical principles, and lean production processes, it systematically explores the root causes behind the formation of air bubbles and presents a comprehensive, effective, and measurable solution to eliminate them.

Part 1: Getting to the Core — A Deep Analysis of Air Bubble Formation

1. Intrinsic Influence of Raw Material Proportions

(1) The Decisive Role of the Water–Cement Ratio (W/C)

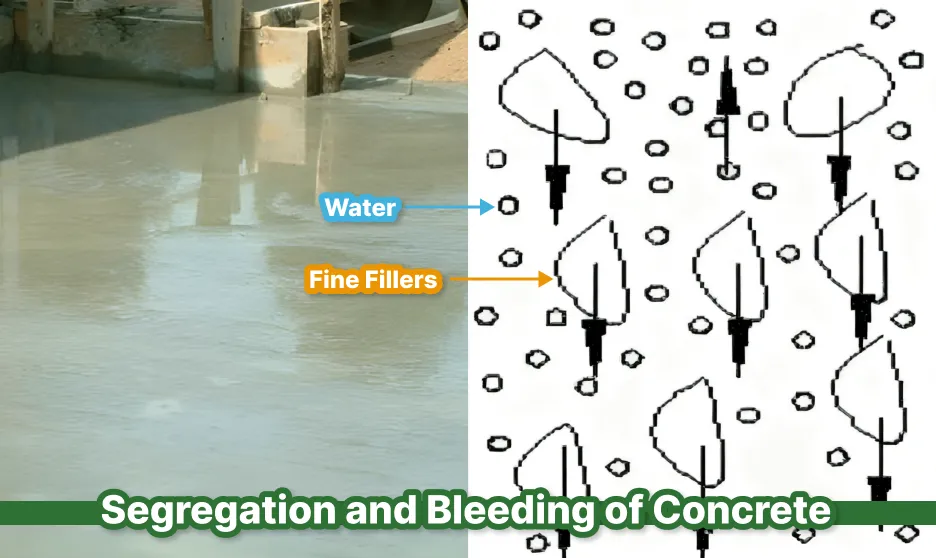

When the water–cement ratio or overall water content in concrete is too high, air bubble formation becomes significantly more frequent.The compressive strength of concrete is inversely proportional to the water–cement ratio. More importantly, an excessively high ratio does not merely mean “too much water” — it triggers two key physicochemical processes: segregation and bleeding. As excess water increases the fluidity of the concrete mix, the heavier coarse aggregates tend to settle (segregation), while the free water rises to the surface (bleeding). During this upward movement, the free water captures or pushes air trapped inside the concrete mixture. Once these air pockets reach the mold surface, they become trapped beneath it, eventually forming visible surface bubbles or voids after hardening. Controlling the water–cement ratio is therefore the fundamental solution to surface air bubble issues in precast concrete.

Research indicates that for foam concrete used as filling or insulation material, the optimal water–cement ratio ranges from 0.45 to 0.50. This range can also serve as a valuable reference for mix design in standard concrete, ensuring sufficient strength while minimizing bleeding and improving surface quality.

(2) The Dual Effects of Chemical Admixtures

Chemical admixtures in concrete represent a complex and multidimensional variable. We can categorize gas behavior in concrete into three levels:

- Unintentionally induced (e.g., excess air caused by grinding aids),

- Intentionally controlled (e.g., air-entraining agents),

- Deliberately created (e.g., in foam concrete).

Grinding aids used in cement production may unintentionally introduce excess air, leading to unwanted air bubbles — this differs sharply from the controlled microbubbles formed by air-entraining agents (AEAs). AEAs are specifically designed to sacrifice a small amount of compressive strength in exchange for improved durability. They intentionally generate uniform, stable microbubbles (typically smaller than 0.3 mm) throughout the concrete matrix, enhancing freeze–thaw resistance and long-term performance. Therefore, the core issue behind surface air bubbles lies in uncontrolled pore formation caused by improper formulation or production processes, not in the intended air entrainment. In mix design and production, it is essential to precisely control the type and dosage of chemical admixtures and ensure complete, uniform dispersion during mixing to eliminate air bubbles caused by unintended chemical reactions.

2. The Impact of Production Processes

(1) Mixing Uniformity and Duration

The mixing process plays a crucial role in concrete preparation, and both insufficient and excessive mixing can lead to undesirable outcomes.

- Insufficient mixing may cause uneven distribution of admixtures or materials, leading to localized concentrations where excess air bubbles form.

- Overmixing, on the other hand, can trap additional air and stabilize it within the mixture, resulting in a higher overall air content in the concrete.

Modern engineering technologies now enable precise control of the mixing stage. For example, setting an accurate mixing duration (typically between 10 to 300 seconds) helps ensure homogeneity. More advanced systems employ image recognition and motor current monitoring to evaluate the load of the mixing motor, allowing operators to determine whether the concrete has reached the desired level of uniformity. This approach reduces the subjectivity of manual judgment, minimizes potential errors, and ensures consistent discharge quality for every batch.

(2) Scientific Management of the Vibration Process

Vibration is a critical step in removing trapped air from freshly mixed concrete and ensuring that the slurry fills the aggregate voids evenly. However, over-vibration, under-vibration, or missed vibration can all result in an increased number of surface air bubbles. The quality of this process traditionally depends heavily on the operator’s personal experience, as workers often rely on sound and tactile feedback to judge whether compaction is sufficient.

Today, vibration technology has evolved from experience-based methods to quantitative management and intelligent control. Research indicates that the spacing between vibration points should not exceed 1.5 times the effective vibration radius of the vibrator — a clear, quantifiable guideline for on-site operation. From an equipment perspective, external (form-mounted) vibrators demonstrate clear advantages over traditional internal (insertion-type) vibrators. Tests show that concrete compacted using external vibrators exhibits significantly fewer surface air bubbles, as the vibration energy is distributed uniformly from outside the mold, avoiding the localized over- or under-vibration that internal vibrators may cause.

For large or complex precast elements, the introduction of intelligent vibration control systems allows for full automation and standardization of the process. These systems use real-time sensors to monitor concrete placement and execute distributed vibration based on preset parameters — vertically by layers and horizontally by sections — followed by a fully automated final vibration after casting to ensure optimal compaction and surface quality. ( Refer to Table 1)

Table 1: Comparison of the Effects of Different Compaction Methods on Concrete Quality

| Compaction Method | Compaction / Uniformity | Surface Voids | Operational Complexity | Applicable Scenarios |

|---|---|---|---|---|

| Internal (Immersion) Vibration | Presence of non-uniform compaction areas | Relatively Numerous | Relies on operator experience and tactile feedback | Small areas or specific locations |

| External (Formwork) Vibration | Uniform and dense concrete compaction | Significantly Reduced | Simple | Formwork casting or large structural members of Precast elements |

| Intelligent Control System | “Real-time layered and zonal control, ensuring optimal compaction” | Minimal | Complexity | “Large-scale, complex projects” |

(3) Ambient Temperature and Release Agent Viscosity

The performance of a concrete release agent is closely linked to the ambient temperature during application. When the temperature exceeds 35°C, the solvent components in solvent-based release agents tend to evaporate excessively, preventing the formation of a uniform and continuous film on the mold surface. This can lead to localized sticking between the concrete and the mold, while over-application or heavy residue buildup may further intensify surface void and air bubble formation. Therefore, it is essential to select a release agent whose chemical properties are compatible with the actual working environment. The chosen product must maintain stable viscosity, film-forming ability, and separation performance throughout the entire production cycle to ensure smooth demolding and a flawless concrete surface.

Part 2: Solutions

(1) Optimizing Mix Design and Material Selection

To effectively solve the issue of surface air bubbles in precast concrete elements, the first step is to optimize the mix design and raw material selection. The cement type, grade, and performance should be thoroughly tested and verified according to relevant standards. Within the allowable specifications, using larger aggregate sizes can help reduce the overall water demand, thereby minimizing the risk of bleeding and improving the surface finish of the precast concrete.

(2) Selecting Appropriate Chemical Admixtures

Choosing the right chemical admixtures is a key factor in air bubble control. For example, using a polycarboxylate-based superplasticizer can significantly increase water reduction, maintaining excellent workability of the concrete mix while minimizing water content. This effectively suppresses bleeding and segregation, creating optimal conditions for bubble-free production. It is also important to select the appropriate defoaming agents, surfactants, and surface brighteners:

- Defoaming agents work by reducing surface tension, preventing air bubble formation or breaking existing bubbles, allowing them to coalesce and escape from the mixture.

- Surfactants and surface brighteners do not primarily target air bubble elimination; instead, they provide collateral benefits by improving bonding and surface finish.

- When used within construction specifications, they can be added in moderation to enhance overall surface quality.

Table 2: Synergistic Effects of Functional Additives on Surface Quality

| Additive Type | Main Mechanism of Action | Effect on Bubbles | Final Product Effect |

|---|---|---|---|

| Defoamer | “Lowers surface tension, destroys bubble film” | Direct defoaming and foam suppression | Significantly reduces the number of surface bubbles |

| Interface Agent | “Enhances bonding strength, densifies the base layer” | “Reduces voids through densification, indirectly suppresses foam” | “Prevents blistering/hollowing and cracking, improves adhesion” |

| Brightener | “Fills micropores, disrupts bubble stability” | Direct degassing/defoaming by disrupting large bubbles | Improves surface finish/gloss and wear resistance |

(3) Focusing on Key Additives: Using High-Performance Concrete Release Agents

Among all chemical admixtures, the release agent serves as the final line of defense against surface air bubbles, acting directly on the concrete surface. Its value goes far beyond simply preventing sticking: it forms a uniform, stable physical or chemical isolation layer between the mold and concrete, ensuring smooth demolding, protecting the mold surface from damage, and extending mold service life.

Release agents can be classified by carrier type into solvent-based, water-based, and carrier-free formulations. With increasing environmental regulations, water-based release agents have become an industry trend due to their low VOC content. Notably, updated Chinese industry standards have imposed stricter requirements for high-quality release agents. Compared with the 2005 version, the new standards:

- Tighten the concrete adhesion limit from ≤5 g/m² to ≤4 g/m²,

- Add criteria for secondary workability on concrete surfaces, corrosion resistance on steel molds, and maximum service temperature.

These changes indicate that a high-quality release agent must deliver efficient demolding while simultaneously meeting environmental, anti-corrosion, and high-temperature durability requirements. A truly high-performance release agent forms an ultra-thin dry film (typically 0.1–1.0 µm) on the mold surface. This provides excellent demolding properties without transferring or leaving any residue on the concrete, eliminating the need for secondary cleaning and ensuring ease of subsequent operations. ( Refer to Table 3)

Table 3: KPI for High-Quality Release Agents

| Performance Indicator | Old Standard | New Standard | High-Quality Release Agent Performance |

|---|---|---|---|

| Concrete Adhesion Residue | ≤5 g/m2 | ≤4 g/m2 | <4.0 g/m2 |

| Corrosivity to Steel Formwork | Non-corrosive | Corrosion area ratio ≤0.2 | Non-corrosive |

| Post-Stripping Surface Treatment | Not Applicable | New Requirement | No cleaning required |

| Maximum Service Temperature | Not Applicable | New Requirement | Meets requirements for specific high-temperature curing processes |

(4) Lean Construction Practices: The Art of Vibration and Casting

Vibration is a core process for removing air bubbles and enhancing concrete compaction. Key practices include:

- Precise Layout of Vibration Points Based on the effective radius of the vibrator (e.g., for a 35 mm hand-held vibrator, the theoretical effective coverage diameter is roughly 10 times the rod diameter), mark and calculate the spacing of vibration points to ensure full coverage and prevent missed areas.

- Quantitative Control of Vibration Duration

Vibrate until surface air bubbles are no longer visible and the concrete surface appears smooth with slight paste exudation. Over-vibration must be avoided, as it may cause aggregate settlement and paste rising, worsening bleeding. The recommended technique is “fast insertion, slow withdrawal”:

- Fast insertion ensures uniform vibration time across upper and lower layers,

- Slow withdrawal allows the concrete paste to fill the void left by the vibrator, preventing gaps. This is especially critical for stiff concrete.

- Equipment Upgrades Prefer external (form-mounted) vibrators, which deliver uniform vibration from outside the mold, significantly reducing surface bubbles and improving mix uniformity. For large-scale projects, intelligent control systems with liquid-level sensors and timed logic control are recommended to automate and standardize vibration, minimizing human error and ensuring consistent quality.

Part 3: Conclusion and Outlook

Addressing surface air bubbles in precast concrete elements is a systematic challenge that requires coordinated optimization across material mix design, production processes, and chemical admixtures. Neglecting any single aspect can compromise the entire outcome. Ultimately, it is essential to recognize that the synergy between proper vibration and High-Performance release agnet provides the final guarantee for flawless surfaces. Perfect vibration ensures internal compaction, while a premium release agent acts as the last physical and chemical barrier for surface smoothness. Therefore, selecting the right release agent is the ultimate safeguard for achieving bubble-free, high-quality precast concrete elements.